Vitrintec’s glass transport

Glass has accompanied mankind for a long time, since it appeared as early as the 4th millennium BC. Refined over many years, it is now available in virtually any conceivable form. Glass is used in many areas of our lives. At Vitrintec, it goes “hand in hand” with aluminium, which often results in the need to transport it. Contrary to appearances, this is by no means an easy and obvious process, if only because the glass we use is often large.

In 1957, the British company Pilkington developed the float glass production process, a revolutionary method that contributed to the mass production of flat glass. Pilkington’s concept has superseded the Fourcault process, a method first developed in Belgium by Émile Fourcault in the early 20th century, which requires glass to be pulled in the opposite direction to gravity, i.e. upwards.

Float glass is a smooth, distortion-free glass that is used to design laminated or tempered glass elements. Thanks to its natural greenish hue and translucent nature, it allows about 87% of light to pass through, unlike flat glass. Float glass owes its unique name to the process by which it is produced. It all starts with a mixture of raw materials such as sand, limestone, dolomite, soda and salt cake. The materials are then melted in a furnace until they fuse together. To produce float glass, molten glass from the furnace is then poured into a chamber containing a bed of molten tin. The reason for using tin is that it is the only metal that remains stable in the liquid state at a high temperature of 600 degrees Celsius. The glass floating on the bed eventually takes the shape of the container and expands to a width of 90 to 140 inches and a suitable thickness that is determined during production.

Pilkington also created a new freight task, not very common at the time. Float glass became available in the standard 3.2 m x 7 m size, but also grew to 3.2 m x 10 m with thicknesses up to 19 mm – encouraging the global transport trailer industry to invent a wide range of sophisticated equipment for transporting an oversized, fragile commodity like glass. At first, the transport industry modified a common rigid design by simply connecting the superstructure to the platform – usually a solid A-frame. Later, British company Supertrucks refined the concept and introduced an external trunk that could be attached to the side of the van, saving internal cargo space.

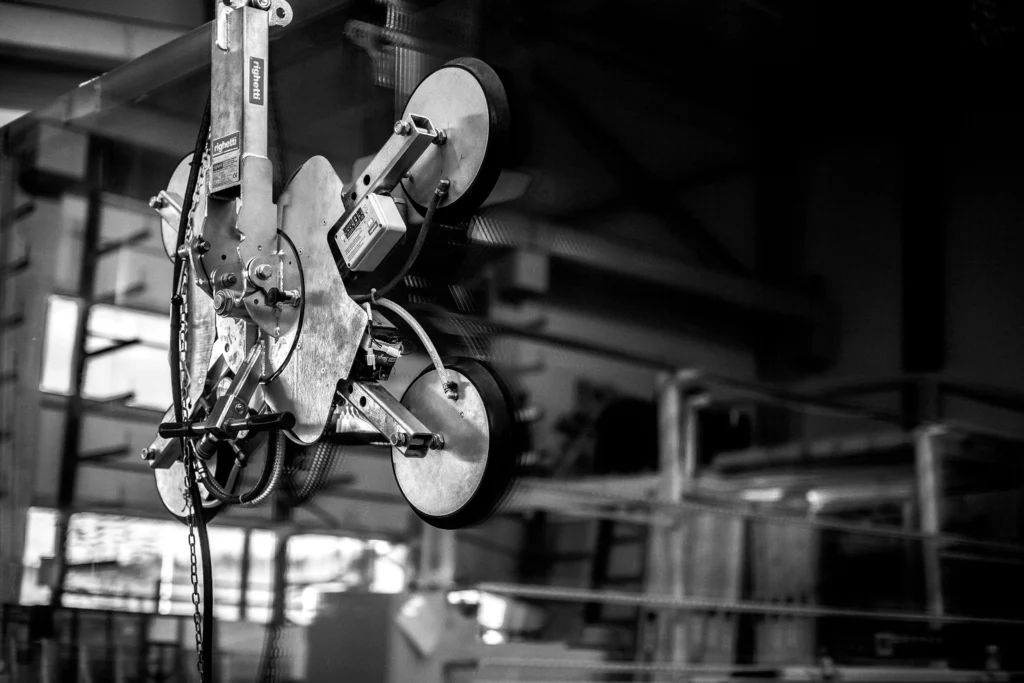

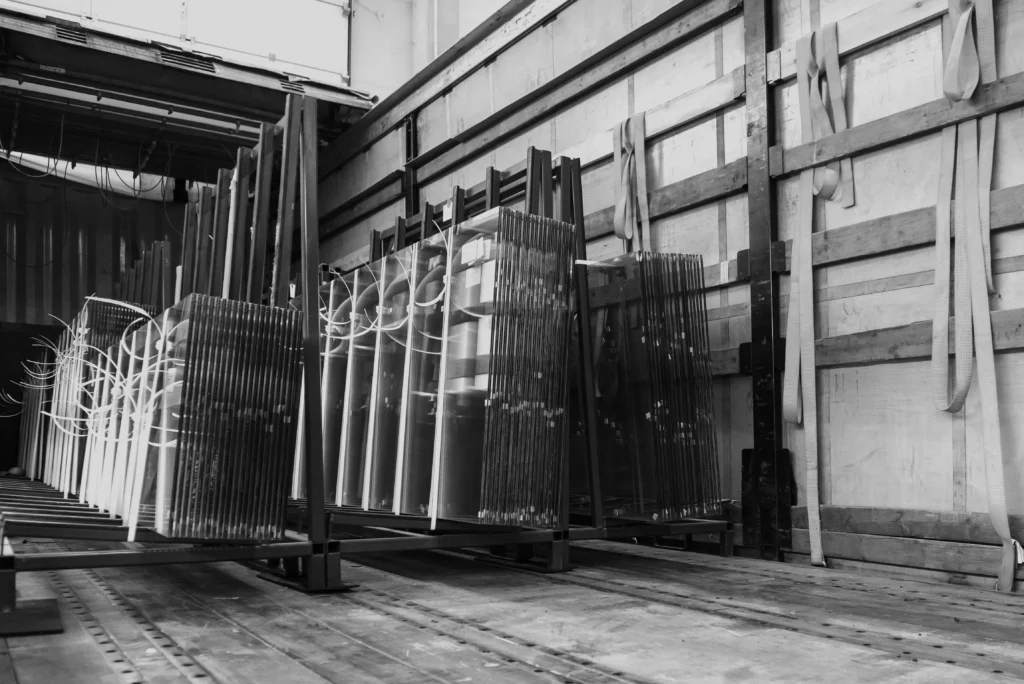

Supertrucks unveiled the new concept at the Glassex exhibition in Birmingham in 1986, and the subsequent success established the company as a leading supplier of glass transport equipment. Although the external racking is a versatile solution, the British concept was limited to 7.5 tonnes GVW and could not provide full protection from wind and weather. After all, water is the nemesis of modern glass transport. All it takes is for a few drops to penetrate the gap between the panes — the panes will then become fused inextricably, effectively rendering the cargo useless. For this reason, the internal glass rack trolleys, which we also use at Vitrintec, have become standard equipment in the European glass transport industry, surpassing the classic external racking design by offering effective protection against moisture.

EWhile industry experts are unable to predict which solution will dominate the future of glass transport, they agree that distance will remain a key factor. According to Glass for Europe, a European trade association, transport costs make long-distance travel by land uneconomical for float glass. “Typically, 200km would be seen as the norm and 600km as the economic limit for most products, although this varies from market to market.” While external racking tends to dominate the short-haul market, the in-loader design we often use at Vitrintec may well remain the primary choice for the long-haul despite the challenges of various curtain rack alternatives that offer greater versatility but less moisture control. Either way, global market data shows that demand for float glass is set to remain high, especially in China. Not only is the PRC the largest consumer of glass in the world, accounting for 50 per cent of the global glass demand as of 2009, but it is also the world’s largest glass producer, accounting for more than 50 per cent of global flat glass production as of that year. It has an astonishing number of glass manufacturing companies and the largest number of float glass production lines in the world.

However, irrespective of how and where the glass is shipped, the most important thing is to use appropriate cargo-securing features, because glass, like any other material, should arrive at the recipient in one piece.